Supply chain complexity presents a simple opportunity for technology

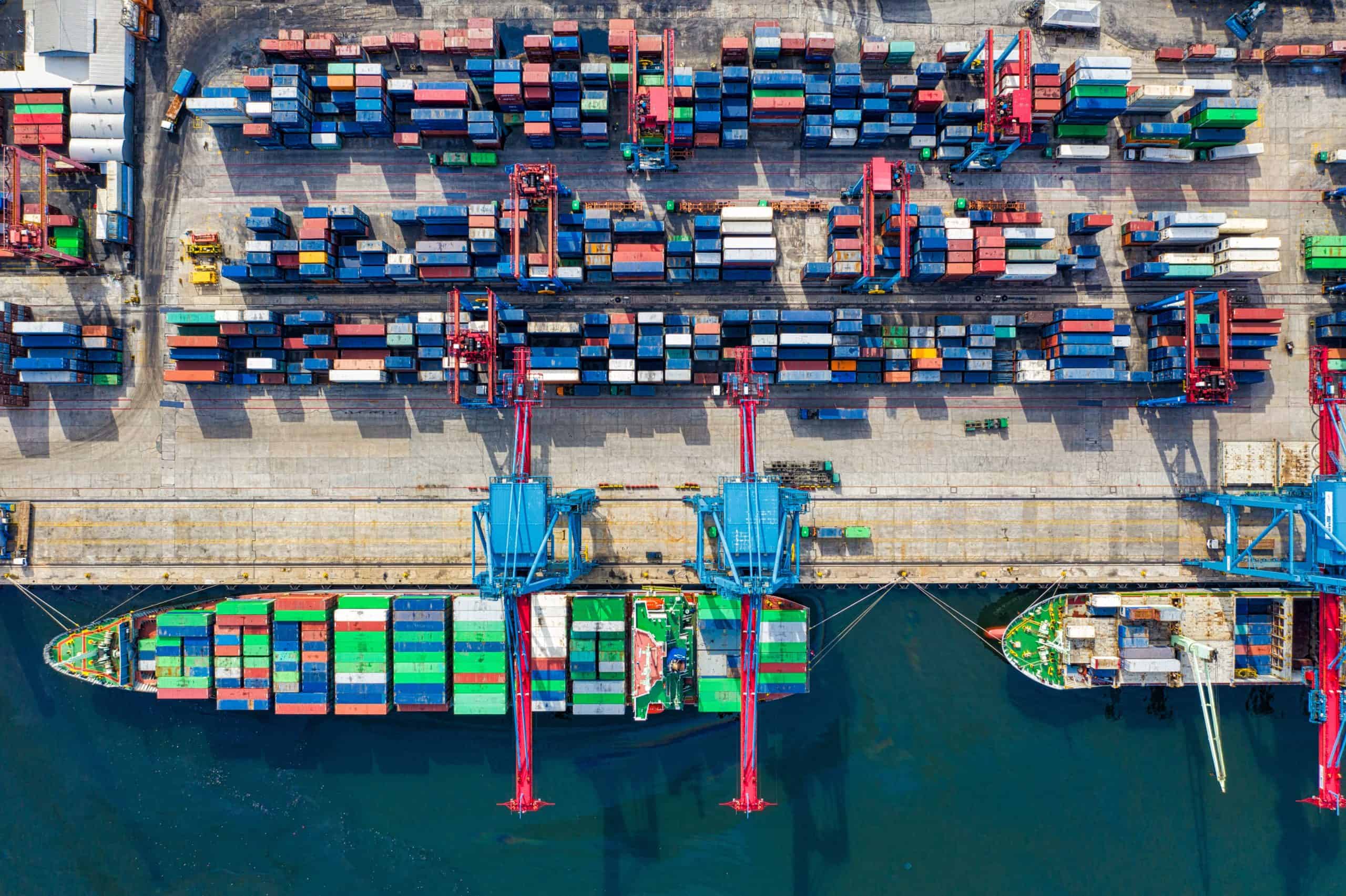

The vulnerabilities inherent in our global supply chains have been brought to the fore in recent months. We’ve seen how semi-conductor scarcity continues to blight the global automotive sector. How shortages in the supply of skills, not just in logistics but in farming, hospitality and manufacturing also, continue to threaten profits and productivity of all manner of businesses. And how capacity shortages on container ships and delays at ports now threaten to steer Christmas off course. The supply chain is our modern-day Grinch…

“It came without ribbons; it came without tags. It came without packages, boxes, or bags” – so too will supply chain evolution after we see it through Christmas…

Plugging gaps and future-proofing supply chains is front of mind for businesses now. A survey of supply chain leaders by McKinsey & Company published last summer suggested that covid-19 had revealed issues that will transform operations for good. After the logjams are cleared, the visas rolled out and when forecourts are replenished, businesses will be looking hard at how they improve both resilience and digitalisation.

While part of the answer for global companies will be to limit exposure to risk, incorporating more regional/domestic supply as part of the mix or reducing the number of unique parts in products, for example, the next normal in global supply chain management will see companies banking on technology to increase visibility and agility across their operations.

IoT and digital twins, AI and machine learning, cloud and 5G. Buzzwords by themselves, but revolutionary capabilities in the right technology stack, transforming how we plan and manage supply chains in future.

They’re already being used for advanced planning to better predict and manage changes in demand and supply. By factoring in a supplier’s exposure to risk (climate, financial, geopolitical), organisations can accelerate their ability to respond to issues. Better yet, by incorporating a digital twin, they’re able to create an advanced digital model of their entire organisation and use it to simulate a wide range of scenarios and changing conditions and put robust contingency plans in place for near every eventuality.

IoT and 5G are also radically changing how responsive industry can be. With the growth of machine communications and the next-gen connectivity standalone 5G allows, businesses will gain “real-time visibility of supply chain performance, risks, opportunities and events”. They’ll know exactly when and where to dedicate resources to either mitigate disruption or to deliver additional value for their customers.

And perhaps the most exciting element of supply chain transformation is the incorporation of intelligence-driven automation which will predict outcomes and make supply chain decisions, considering a number of factors not humanely possible!

At Babel, we’re working with a number of clients at the forefront of this transformation. With supply chains under the spotlight, many CIOs and their finance counterparts on the board are looking at how they can not only weather the current storm, but how they can protect themselves against similar risks in future. In a competitive space, cutting through and articulating your unique value proposition can be difficult – but reaching the right audience, at the right time, with the right message is our bread and butter. Whether you’re a next generation ERP vendor or an application framework business looking to solve supply chain challenges and sell-in to this space, Babel can help you stand out from the crowd.

Perhaps this year, it will be software, not Santa, that is most welcome at Christmas time…